Safety filling and weighing systems for silos

Overview

The safety system in the silo filling system consists of an electronic supervisory control unit which operates one or more silos, accompanied by a number of control devices such as a sleeve valve, a truck connection flange with hose detection, maximum and minimum level indicators, continuous radar indicators, pressure indicators, overpressure safety valves, filtration equipment and an alarm siren.

Masiste offers its customers silo filling and safety systems with the maximum European guarantee

Functionality The silo safety system can be used for silos that are filled via truck with powder or granular materials. Damage to the silo or its accessories occurs mainly during the silo filling operation. This is due to the risk of overfilling or over pressurisation. The multi-component filling system prevents overfilling and overpressurisation, which avoids damage to the silo, filter or other accessories, and reduces the risk of dust emission into the atmosphere.

Technical features and benefits

- Avoids damage to the silo and its accessories.

- Reduces the risk of atmospheric pollution.

- Eliminates the risk of filling the wrong silo.

- Automatically starts and stops the cleaning filter.

- Electronic pressure indicator gives indication of when the filter may need checking.

- Internal pressure monitoring of each silo.

- Maximum full indication.

- Reveals presence of compressed air to the filter (if compressed air is used) and sleeve valve.

Silo filling and safety control

Masiste markets and distributes silo filling control and silo safety systems. The silo safety system works on the basis of a central electronic silo monitoring and control unit and a kit with an electrical control panel for each silo, a silo connection flange, a sleeve valve, a truck connection flange, a maximum level indicator, a pressure indicator or an electronic pressure indicator, a filter pressure switch, a safety valve and an alarm siren.

Weighing system for silos

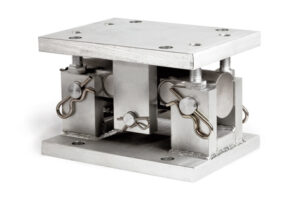

In Masiste you can find different weighing modules in silos and tanks approved to be converted into scales. You can find the SWB505 MultiMount 5K 4,4Tn, the model SWC515 Pinmount 7,5 100Tn, the model 420 2,5 30 Tn, the model 460 5tn 100tn and an endless number of modules in silos and tanks. Trust Masiste to purchase your silo and tank weighing systems for your industrial activity.

WEIGHING SYSTEMS FOR SILOS, STOCK CONTROL, MIXING, DOSING AND FILLING IN BINS, TANKS AND REACTORS.

- Weighing control from small capacities up to large storage silos of 600t per support point.

- High accuracy and respectability of weighing values.

- ATEX certified load cells, sum boxes and indicators, for work in potentially explosive gas and dust atmospheres.

- Fully stainless steel construction and hermetically sealed. IP 68/IP 69K protection for use in applications requiring cleaning by high pressure water jets such as in the food industry, farm cleaning…

- Wide operating temperature range for the most extreme environments, with

operating temperatures from -50 °C to +95 °C and optionally up to +200 °C. - Mounting accessories with anti-tilt system and silent-block, which provide the system with easy assembly and perfect transmission of force against thermal expansion, torsion, structural deformation and vibrations.

- Weight indicators, transmitters and signal repeaters of easy installation, setup, calibration and multiple communication systems: RS-232, RS-485, ProfiBus, Profinet

and analogue. - Weighing is present in all sectors and is used as the main unit of measurement.