Bagging and filling

Masiste is a specialist in bagging and filling solutions for production lines in all industrial sectors. Masiste’s bagging and filling systems, which have the maximum European manufacturing guarantee, allow the bagging and filling of a wide range of products: cements, sands, liquids, gravels… maintaining stable production environments through the exhaustive control of humidity, fluidity, ventilation, dust composition and compaction behaviour. Do not hesitate, buying Masiste bagging and filling systems will be the ideal solution for your industry or business.

Big-bag chargers

The RBB big-bag chargers distributed by Masiste consist of a frame and a complete loading unit equipped with an inflatable seal to prevent dust leakage during use. Adapted for the efficient loading of big-bags, they are attached to the 4 tensioners at the top corners of the frame. The bag loading spout is then placed over the station loading spout and starts filling when the bag loading spout is inflated. Lifted by forklift, they are transferred to their destination. Made of carbon steel and 304L / 316L stainless steel, they are equipped with 4 tensioners for the correct positioning of the FIBC. Modular in design, the big-bag loaders are easy to install and fill in the absence of dust (even in compacted dust).

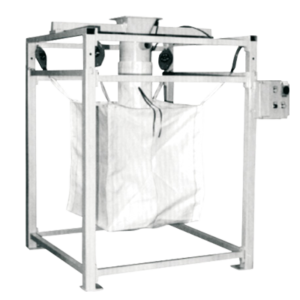

Big-bag dischargers

The SBB big-bag dischargers are unloading systems for medium-sized flexible bags or FIBC (Big Bags). They are easy to attach to the support and unloading frame thanks to the four hooks on the frame. Thanks to a lifting carriage, the big-bag unloaders can open the bags through the hopper hatch by resting the bag on the edge of the hopper.

The SBB big-bag dischargers are manufactured according to a modular design in carbon steel and 304L/316L stainless steel, with height adjustment for FIBC loading with the elevator, with monorail for the installation of a lift and a hopper complete with access hatch for FIBC opening, electric vibrator as an aid to material unloading, vibrating cone with a diameter of 1. 250 mm or 1,500 mm diameter), 219, 273 and 600 mm diameter outlet, vibration damping, dust-tight seal and complete bag discharge also with compressed powder.

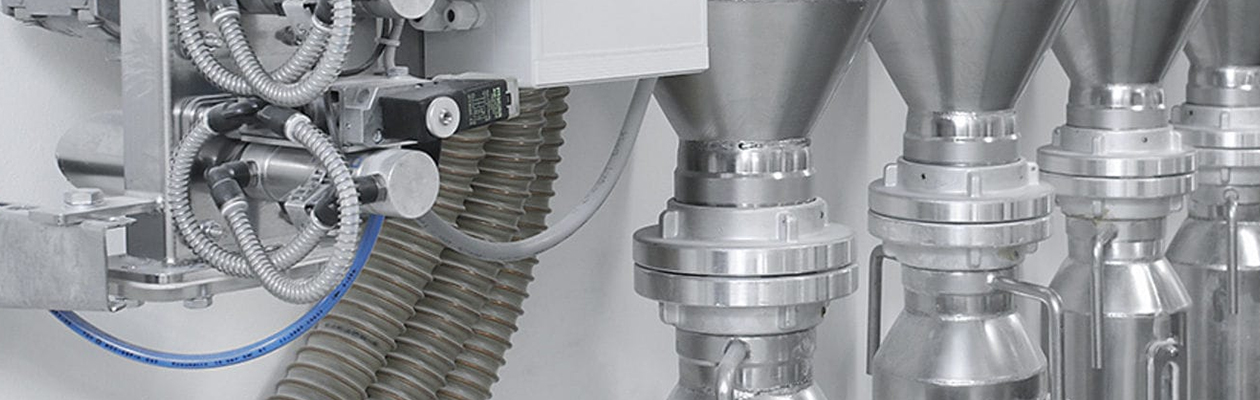

Net weight belt bagging machine

The Masiste net weight bagging machine with belt has a belt feeding system. This model is the most versatile for most products due to its good behaviour and treatment of the material to be bagged. The Masiste net weight belt bagging machine stands out for its airtightness and ease of cleaning. Equipped with inlets for dust suction and air decompression, its production capacity is up to 12 bags per minute, speeding up production in productive sectors such as agriculture, industry, etc.

Net weight bagging machine with screw conveyor

The screw conveyor bagging machine distributed by Masiste is a weigher with screw feed specially designed for pulverulent, ground or unstable products. Screw feeders are built with progressive pitch to avoid product caking. The screw feed bagging machine allows an industrial production of up to 10 bags per minute. Buying the net weight bagging machine with screw is the ideal solution for the distribution of your production, materials and raw materials in your business.

Automatic bagging machines

Masiste automatic bagging machines are used for polyethylene, paper, plasticized paper and polypropylene raffia bags, being suitable for products such as sand, gravel, special fertilisers, substrates, mineral fertilisers, organic fertilisers… Automatic bagging machines allow automatic bag forming, filling and sealing. Masiste distributes automatic pneumatic bagging machines with fluidisation, horizontal and vertical turbine bagging machines, stainless steel vertical bagging machines and tubular bagging machines up to 2000 bags per hour.

Valve bag filler

Masiste markets and distributes valve bag fillers with an operating capacity from 5 to 50 kg. The valve bag fillers have a power supply by turbine, screw or fluidisation. This model of valve bag filler is suitable for all products using this sealing system, with a production volume of up to 8 bags per minute and automatic or semi-automatic operation. Buying Masiste valve bag fillers will be the ideal solution to improve the performance of your production lines, with which you will be able to fill bags easily.